Inconsistent net performance disrupts growth cycles

Commercial mushroom production and other specialized horticultural setups often rely on netting to provide structure and support for both growing medium and casing soil. However, low-grade nets can stretch, tear, or become clogged, leading to uneven coverage and poor airflow. In mushroom cultivation, a small imbalance in moisture or air circulation can produce irregular flushes, contamination issues, or suboptimal yields. Meanwhile, cleaning subpar nets between growing cycles becomes a labor-intensive chore, and if debris remains trapped, it risks infecting the next batch.

Inconsistent net performance disrupts growth cycles

Commercial mushroom production and other specialized horticultural setups often rely on netting to provide structure and support for both growing medium and casing soil. However, low-grade nets can stretch, tear, or become clogged, leading to uneven coverage and poor airflow. In mushroom cultivation, a small imbalance in moisture or air circulation can produce irregular flushes, contamination issues, or suboptimal yields. Meanwhile, cleaning subpar nets between growing cycles becomes a labor-intensive chore, and if debris remains trapped, it risks infecting the next batch.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Enhance cultivation efficiency with durable, easy-to-clean netting

Inconsistent net performance disrupts growth cycles

Commercial mushroom production and other specialized horticultural setups often rely on netting to provide structure and support for both growing medium and casing soil. However, low-grade nets can stretch, tear, or become clogged, leading to uneven coverage and poor airflow. In mushroom cultivation, a small imbalance in moisture or air circulation can produce irregular flushes, contamination issues, or suboptimal yields. Meanwhile, cleaning subpar nets between growing cycles becomes a labor-intensive chore, and if debris remains trapped, it risks infecting the next batch.

.png)

For farmers managing large operations, any ongoing problem with nets slows down productivity and raises costs. If the nets shrink or twist after repeated use, they may no longer fit the trays or tunnels correctly. This misalignment leads to extra time spent adjusting or improving solutions. Additionally, contaminants can hide in frayed areas, increasing the likelihood of disease spread and forcing more frequent disinfecting routines.

Strong, reliable netting supports better harvests

Effective netting ensures a uniform layer of casing soil, helping mushrooms develop more evenly. It also allows growers to manage temperature, humidity, and airflow with greater precision, contributing to consistent harvest cycles. When nets are easy to clean and maintain, the downtime between batches shrinks, so more cycles can occur in the same season. That efficiency translates to increased revenue and a more dependable supply for buyers.

High-quality nets also reduce the risk of contamination. In mushroom farming, a single outbreak of mold or bacteria can compromise an entire crop. By using netting that doesn’t degrade easily and can be thoroughly sanitized, growers minimize potential hot spots for microbial growth. This preventative measure not only saves money but also enhances a farm’s reputation for delivering clean, top-grade produce.

Inconsistent net performance disrupts growth cycles

Commercial mushroom production and other specialized horticultural setups often rely on netting to provide structure and support for both growing medium and casing soil. However, low-grade nets can stretch, tear, or become clogged, leading to uneven coverage and poor airflow. In mushroom cultivation, a small imbalance in moisture or air circulation can produce irregular flushes, contamination issues, or suboptimal yields. Meanwhile, cleaning subpar nets between growing cycles becomes a labor-intensive chore, and if debris remains trapped, it risks infecting the next batch.

Strong, reliable netting supports better harvests

Effective netting ensures a uniform layer of casing soil, helping mushrooms develop more evenly. It also allows growers to manage temperature, humidity, and airflow with greater precision, contributing to consistent harvest cycles. When nets are easy to clean and maintain, the downtime between batches shrinks, so more cycles can occur in the same season. That efficiency translates to increased revenue and a more dependable supply for buyers.

High-quality nets also reduce the risk of contamination. In mushroom farming, a single outbreak of mold or bacteria can compromise an entire crop. By using netting that doesn’t degrade easily and can be thoroughly sanitized, growers minimize potential hot spots for microbial growth. This preventative measure not only saves money but also enhances a farm’s reputation for delivering clean, top-grade produce.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

How NICOLON growing and casing nets boost productivity

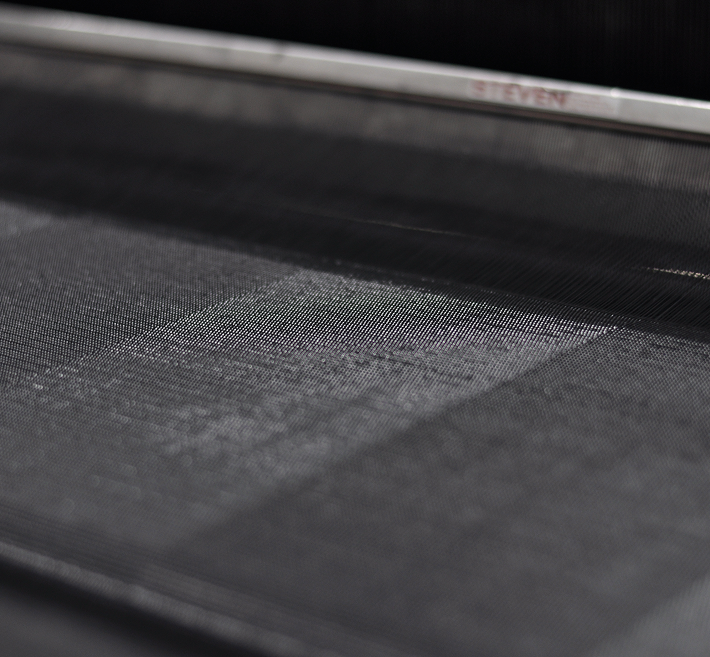

NICOLON nets are engineered with blended monofilament yarns, creating an open structure that allows thorough cleaning. This design prevents material buildup, reducing both contamination risk and the amount of time spent scrubbing. Because these nets resist stretching and shrinking, they retain their original shape, fitting reliably into trays or onto conveyor systems cycle after cycle.

For mushroom casing, NICOLON nets can be integrated with automated filling machines, helping distribute soil evenly across compost. By adding soil or supplements this way, farms achieve more uniform growth conditions and reduce labor. The nets also withstand repeated mechanical forces, so they hold up over multiple production rounds without tearing or losing tension. Altogether, NICOLON nets simplify daily operations and reinforce long-term consistency, delivering significant value for professional growers.

Key benefits

Open, monofilament structure

Allows thorough cleaning and faster drying

Minimal distortion

Resists stretching and shrinking, preserving a secure fit

Easy integration

Works well with automated systems for casing soil distribution

Highly durable

Stands up to repeated use without tearing

Improved hygiene

Reduces contamination risks during and between cycles

Versatile sizes

Tailored to different tray dimensions and filling setups

.png)