Operational excellence with NICOLON nets

In large-scale composting tunnels, where temperatures and airflow must be carefully controlled, extracting the final product can become a bottleneck. High-friction surfaces or poorly fitting netting systems mean workers or automated equipment struggle to pull the compost out efficiently. This leads to frequent snags, residual compost left behind, and extra time spent cleaning up. When each tunnel is delayed, the overall throughput declines, creating backlogs and raising labor costs.

Operational excellence with NICOLON nets

In large-scale composting tunnels, where temperatures and airflow must be carefully controlled, extracting the final product can become a bottleneck. High-friction surfaces or poorly fitting netting systems mean workers or automated equipment struggle to pull the compost out efficiently. This leads to frequent snags, residual compost left behind, and extra time spent cleaning up. When each tunnel is delayed, the overall throughput declines, creating backlogs and raising labor costs.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Tunnel & glide nets - proven performance & reliability

Operational excellence with NICOLON nets

In large-scale composting tunnels, where temperatures and airflow must be carefully controlled, extracting the final product can become a bottleneck. High-friction surfaces or poorly fitting netting systems mean workers or automated equipment struggle to pull the compost out efficiently. This leads to frequent snags, residual compost left behind, and extra time spent cleaning up. When each tunnel is delayed, the overall throughput declines, creating backlogs and raising labor costs.

Poor airflow within the tunnel is often a challenge. If materials do not receive proper oxygen levels, decomposition can stall or become uneven, leading to inconsistent quality and possible odor problems. Each phase – whether it is the hot initial stage (Phase 1) or the cooler finishing stage (Phases 2 and 3) – requires distinct conditions that standard nets might not handle well if they stretch, tear, or impede ventilation. NICOLON tunnel and glide nets offer the right solution.

Smooth extraction boosts compost quality

When compost can be removed from a tunnel quickly and cleanly, each phase moves on schedule. This efficiency drives cost savings and increases the total volume of compost processed. In that case, teams free up time to focus more on adjusting conditions, monitoring temperature, and ensuring consistent quality. Streamlined removal also minimizes cross-contamination between batches, preventing partially decomposed material from mingling with fresh inputs or fully matured compost.

A well-managed tunnel translates to higher-quality compost overall. With uniform aeration and precise temperature control, microbes break down organic matter more completely, yielding a product that is rich in nutrients and free from foul odors.

Operational excellence with NICOLON nets

In large-scale composting tunnels, where temperatures and airflow must be carefully controlled, extracting the final product can become a bottleneck. High-friction surfaces or poorly fitting netting systems mean workers or automated equipment struggle to pull the compost out efficiently. This leads to frequent snags, residual compost left behind, and extra time spent cleaning up. When each tunnel is delayed, the overall throughput declines, creating backlogs and raising labor costs.

Smooth extraction boosts compost quality

When compost can be removed from a tunnel quickly and cleanly, each phase moves on schedule. This efficiency drives cost savings and increases the total volume of compost processed. In that case, teams free up time to focus more on adjusting conditions, monitoring temperature, and ensuring consistent quality. Streamlined removal also minimizes cross-contamination between batches, preventing partially decomposed material from mingling with fresh inputs or fully matured compost.

A well-managed tunnel translates to higher-quality compost overall. With uniform aeration and precise temperature control, microbes break down organic matter more completely, yielding a product that is rich in nutrients and free from foul odors.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

How NICOLON

tunnel and glide nets improve efficiency

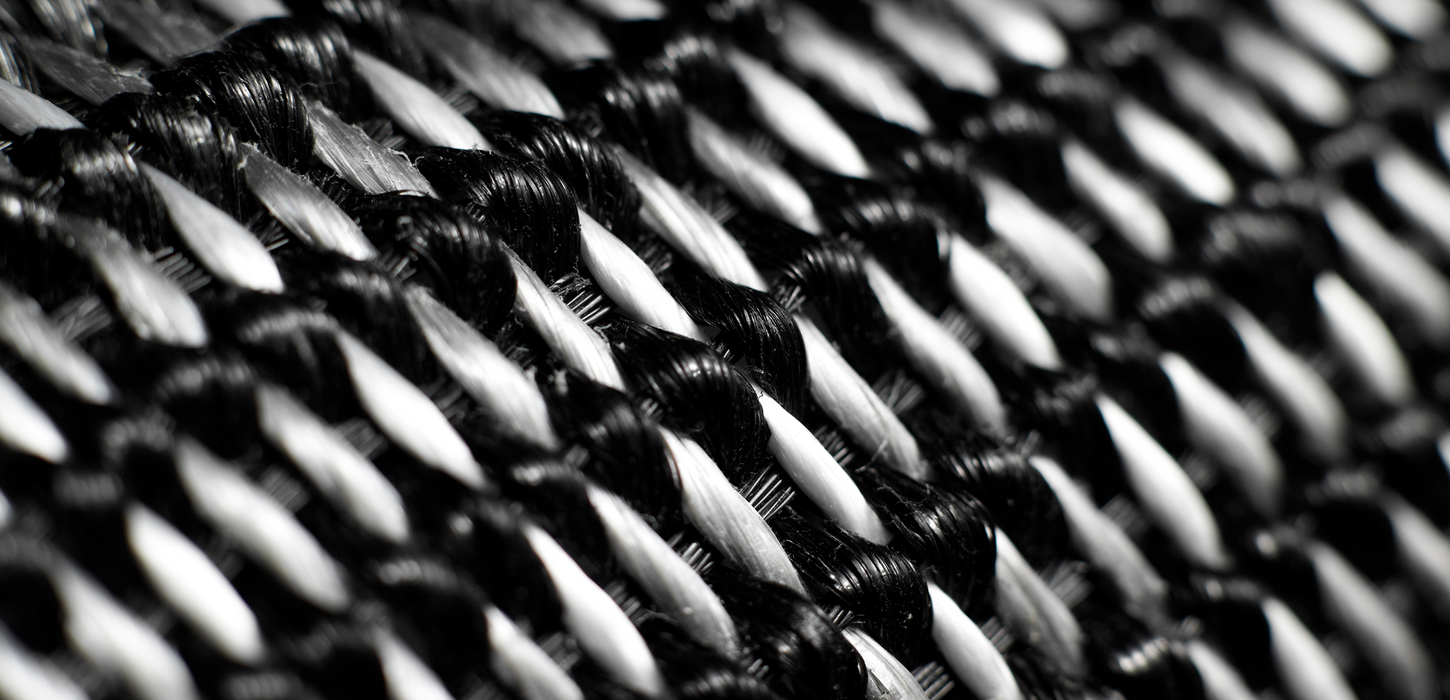

NICOLON tunnel nets are engineered to provide reliable aeration while withstanding repeated use in high-temperature environments. Different types (R176, R875, R186) match the unique requirements of each composting phase, ensuring they maintain structural integrity at the appropriate temperature ranges.

By pairing a tunnel net with a glide net, operators reduce friction making it far easier to pull heavier compost loads. The glide net sit below the tunnel net and this combination drastically cuts the friction with the concrete floor, speeding up the extraction process and enhancing the lifetime of the tunnel net. Both nets are designed for durability, so frequent cleaning after each batch does not quickly degrade them. NICOLON offers different products with different weight capacities and heat tolerances, making it simple to select the best fit for each stage of compost production.

Key benefits

Reduced friction

Glide nets significantly lower the force needed to pull compost

Phase-specific design

Tailored net types for each composting stage

Improved aeration

Ensures consistent microbial activity and temperature control

Prolonged net life

Durable materials resist tearing or heat damage

Faster turnaround

Speeds up emptying tunnels and starting new batches

Custom sizing

Options that suit various tunnel dimensions and operational needs

.png)